Cultivation

Passion + Planning = Profit

Do you have a green thumb and a passion for the cannabis plant? Great! What about extensive experience in facility engineering, propagation schedules, IPM solutions, nutrient regimens, and regulatory compliance? Well, that’s where we come in.

Cultivating cannabis isn’t just growing plants. To succeed, you must be prepared to grow plants under strict regulations, with high start-up costs and a rapid path to scale and efficiency. Your upfront planning, design, and engineering are critical so that you can convert your early investments to profit as quickly as possible.

Building a thriving cannabis cultivation business takes much more than just a passion for the plant.

The good news is that cannabis cultivation can be predictably profitable if it’s well-planned and executed. Canna Advisors provides methodology-specific best practices and SOPs, employee training, nutrient protocols, integrated pest management solutions, propagation calendars, and detailed planning for quality control, inventory control, and facility design. Wholesale operations must also be sales-driven to succeed.

Contact us for a project-based assessment or hourly consultation to get started planning your cannabis cultivation business.

Success Is in the Details

Cultivating high-quality cannabis can be a hobby. Cultivating high-quality cannabis at commercial scale is a design and engineering project -- a blend of specialized horticulture and manufacturing.

The cannabis plant has unique needs, especially at scale. These include:

- Water Requirements: Cannabis is a thirsty plant that needs plenty of water. For comparison, some cannabis cultivation methods require almost double the amount of water per square foot as a wine-grape vineyard.

- Consistent Propagation Methodology: Plants that produce the best yields all start as strong clones. Cultivators must establish a clear process for propagating plants to their prime advantage. Many cultivators accept high levels of plant mortality at this stage, but taking good care in the propagation stage allows cultivators to build their plant population from the best of the best.

- Optimized Cultivation and Harvest Timelines: Profitable cultivators engineer their production schedules to remove bottlenecks and shortages. Designing cultivation and harvest timelines effectively optimize your entire process flow and maximizes facility output.

- Environment and Nutrients: Different strains of the cannabis plant require different environments and nutrient regimens to reach their optimum growth potential. Breaking larger grow rooms into smaller areas and installing a fertigation system capable of sending different nutrient batches to different plants allows you to customize environmental and nutrient conditions to each strain.

In the highly controlled and competitive cannabis cultivation space, getting the details right can be the difference between profitability and failure. We have helped successful clients plan, design, and open cultivation operations across the country. Let us help you grow toward success.

Is Cultivating Cannabis Your Best Fit?

Determine if running a plant-growing operation is right for you

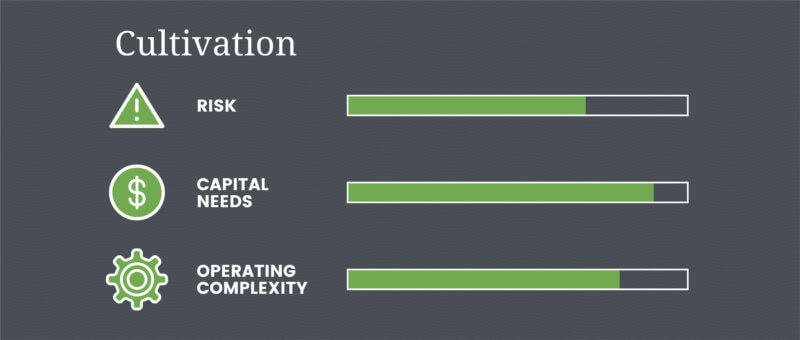

The graphic above gives a general representation of the risks, capital needs, and operating complexity of a cannabis cultivation business. These specific factors may vary depending on your business vision and state regulations.

Art + Science + Business

People have been growing cannabis under a wide variety of conditions for millennia. But producing cannabis for commercial-scale introduces a host of new expectations and requirements, including consistent chemical profiles, predictably high yields, and meeting compliance and quality standards.

The most successful commercial cannabis cultivations are a complicated balance of art, plant science, and business management. Be sure to avoid these common cultivation mistakes and consider the following as you decide if you’re up to the challenge:

- Methodology - Do you want to grow in a greenhouse, a warehouse, or outdoors? What lighting, medium, fertigation, and odor mitigation will you use? What type of automation will you implement? How you’ll grow your plants drives all other decision points -- the amount of money you’ll need, the facilities and equipment you’ll have to obtain, and the quality and yield of the cannabis you can expect to produce. Determining the details of your methodology upfront will pay substantial dividends as you create the ideal facility for your cultivation business.

- Capitalization - Without specific, accurate financial modeling for your business goals, you can run out of money before you even get a cultivation operation up and running. Planning for adequate funding will enable you to anticipate delays or slowdowns and budget accordingly.

- Quality - Sourcing quality plant genetics and strains is the most overlooked and potentially ruinous part of initial operations. Growing techniques are also vitally important to the quality of cannabis plants. Cultivators must pay attention to each individual strain and plant, making adjustments to nutrients and environmental conditions in order for them to thrive.

- Staff - An experienced Director of Cultivation is an owner’s best investment, especially if you’re new to cannabis growing. Running a successful commercial cultivation operation requires planning ahead and addressing challenges before they become insurmountable problems, which means you need cannabis experience and expertise on your team. Read more about how to build a cultivation team that stands the test of time.

The success or failure of a commercial cannabis cultivation is often determined before plants are ever put into soil. Canna Advisors will help you make the best decisions and design operating plans for your optimal productivity, quality, and efficiency. Take advantage of our expertise, tools, and proven processes to ensure your cultivation investment pays off for years to come.

Start Your Cannabis Cultivation Business

Expert cultivation guidance from startup to operation.